Loading ...

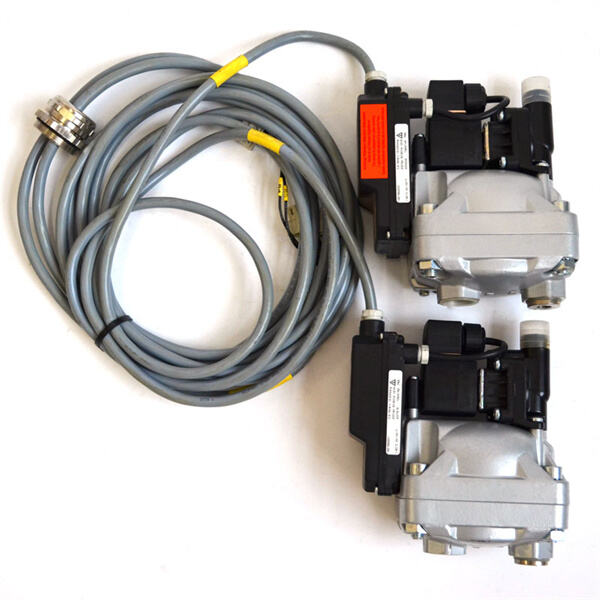

One of the most crucial & fundamental parts in an air compressor is an Air Compressor Valve. It is this valve which aids the compressor for controlling in-and-out with air. The compressor would not operate properly if they were missing. Intake valves: The first type is the intake air compressors valve and second type of compressor valve, as already discussed in our previous category i.e. Suction check Valves.

It is the one that allows air coming from the outside through intake valve. It takes in clean air that is compressed within the device. First step of it. Conversely, the discharge valve works by providing an escape route for compressed air after it has been pressurized. This air is usually critical to fueling different equipment or machines.

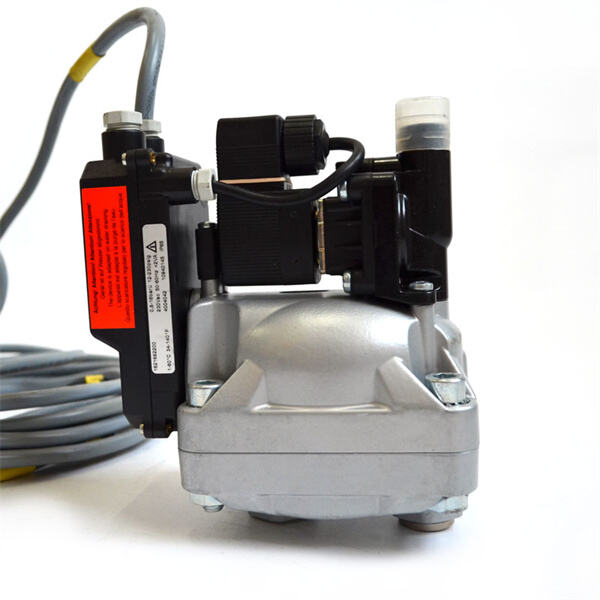

The valve must first be the same size as the compressor. If the valve is too bendy, then it will have much trouble letting in every air - and this means that your compressor will be struggling harder than ever before. The additional effort will wear the machine out. Conversely, if the valve is too large it may use more energy and can possibly end up costing you money in excess later on.

The next that we are going to discuss is the type of valve what you require. Each variety of compressor uses a distinct type of valve. For example, some compressors are made to run on high-pressure air and requires special valves that can withstand the pressure. Therefore, it is critical that the right valve for your compressor be selected.

Stuck Open- If the valve is stuck open, it means that your compressor will keep continually running which could cause overheating. In case something like that happens, it is crucial to act fast. You could always try and clean out the valve if other things are not possible, completely replacing it.

You will be surprised to know that even the valve might get leakety and air has started leaking out. This is possible only if the gasket or valve o-ring get damaged. Therefore, it is critical to rectify this the moment you identify air leakage. If you find it to be the gasket or o-ring, then fix this and should stop your leak.

In short, an air compressor valve is a crucial element of any air compressor. It is responsible for the management of airflow in and out of that Part.onreadystatechange = function () { Addthis.style(function();way machine. There are two different types of valves which serve their own purpose: intake valve and a discharge valve.

From air compressor valve component design and manufacturing to system integration and after-sales support. Support is available 24 hours every day. Global Air Compressor Solutions understands that its clients are the main focus of our work. We work closely with them to develop custom solutions that add value.

We export to more than 58 countries. Our products are very air compressor valve in the United States, Russia, United Arab Emirates (UAE), Indonesia, Thailand Colombia, Saudi Arabia Mexico, Kazakhstan South Korea, Morocco, Senegal Canada, Israel Bolivia, Peru, Singapore, and other countries.

We work to create air compressor valve relationships through providing outstanding services, support, and customized solutions. We also support OEM. Our team of highly skilled technicians and engineers is constantly pushing the boundaries of technology, generating innovative solutions that meet the ever-changing demands of our customers. Thank you for taking a look at Alsman as a trusted partner in compressor excellence.

We air compressor valve Solution and products for Industrial Engineering Project in the world. Include Industrial Screw Air Compressor, Air Tank, Air Pump, Industrial Engineering Machinery Equipments and other Spare Parts. In addition, We also participates in projects to overhaul motors and also maintains motors of various types.