Loading ...

In short, a check valve in an air compressor is one of those very small yet highly crucial components that contribute to the seamless operation of the appliance. It is essentially a fancy gate-way regulating the flow of air in the compressor system. This valve is planted between the tank where the air is stored and the pipe through which air leaves outside. This is the crucial part where it allows compressed air to escape out into the pipe but do not let any air come back in. This one-way flow is very important as it ensures an even air pressure, which needs to be maintained for the compressor to work properly.

Also, there are lots of advantages to using a compressor check valve. The most important point, it saves energy for the air compressor. A valve that stops air from returning into the holding tank cuts back on how tough a compressor must work to have adequate pressure. This saves energy, as well reducing the compressor wear and tear allowing it to work better for longer.

Security is yet an additional essential benefit that features a compressor check valve. You see, a compressor is used to produce high-pressure air (which can get quite dangerous when itiling unchecked). The compressed air can become released or stream back into the tank, which may subsequently burst resulting in causing injuries and physical damage. The compressor check valve is vital for preventing this type of disaster by making the compressed air flow in only one direction.

If the compressor check valve is not working correctly, this can cause a variety of air pressure related issues and may prevent your compress from providing compressed air. If the valve is broken, one of the most obvious symptoms would include difficulty in keeping enough pressure by compressor. Before replacing all your parts, remove the valve from the compressor and check it for damage or wear.

If the valve is broken, you will need to buy a new one. If you do need to remove your handles, disconnect the air lines from both the tank and outlet pipe. After doing that, gently release the old valve [][] and replace it with a new one. With the new valve in place and working, reconnect your air lines, then you are good to go with a fully functioning compressor again!

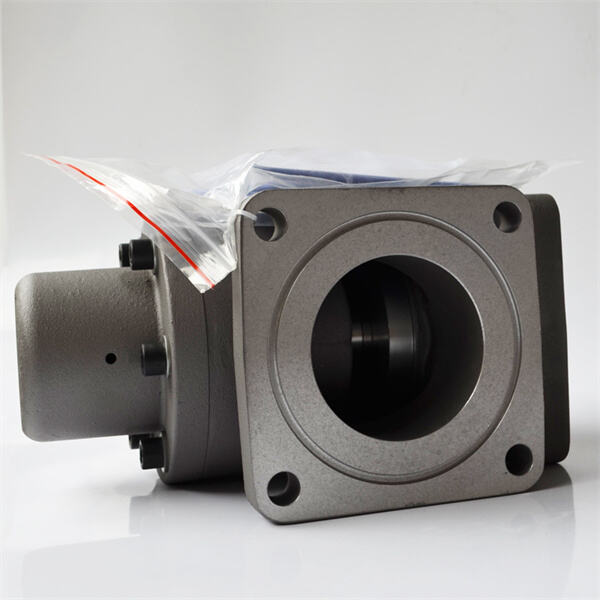

Compressor check valves are of different types made for specific areas, and the appropriate one must be used according to circumstances. A common type of fuel check valve that is used in this application can be called an In-Tank Check Valve and I will explain how it works. The check valve is mounted directly into the compressor tank, and it in fact prevents backflow of compressed air meaning that your pressurized air stays where its supposed to be; inside the tank itself.

To resolve this issue, you will have to remove the compressor check valve and examine it closely for any signs of wear or damage. In case the valve seems to be malfunctioning, you will need a new one. If the valve is merely stuck, it may be feasible to gently free by tapping lightly with a hammer or working side-to-side using pliers. After you dislodge the valve connect with had to compressor and check if everything is in working order.

We also provide OEM assistance for OEM. Our team of experienced technicians and engineers are always pushing the compressor check valve of technology, generating innovative solutions to meet the changing demands of our customers. We thank you for taking a look at Alsman as a trusted compressor partner. quality.

Our business mainly offers compressor check valve, equipments, and accessories for compressors of the world's most renowned brands. We are also engaged in air compression systems as well as vacuum system design consultation Engineering project, repair and maintenance services. We exported to over 60 countries. Products are sold to the United States, Russia, United Arab Emirates, Indonesia, Thailand, Colombia, Saudi Arabia, Mexico, Kazakhstan, South Korea, Morocco, Senegal, Canada, Israel, Bolivia, Peru, Singapore and other countries

From custom-designed component design and manufacturing to system integration and after-sales support. 24/7 online support available. Global Air Compressor Solutions understands that its clients are the center of our operations. We partner compressor check valve with our clients to create custom solutions that maximize the value.

We supply products and solutions for industrial engineering projects around the world. Include compressor check valve Screw Air Compressors Air Tanks, Air Pumps, Industrial Engineering Machinery Equipments, and other Spare Parts. In addition we also take part in projects to maintain motors and repairs a range of motors.