Loading ...

An industrial air compressor dryer is a unique machine that has been purposely manufactured for the removal of water from compressed air. Compressed air is the water (or moisture) in that has evaporated from liquid. This gets the air nice and dry for use. Benefits of an Industrial Air Compressor Dryer This is advantageous as it will help prevent damage to the compressed air using machines. It leads to rust and other forms of damage in machines when air has moisture. Rust — a corrosion that can erode the parts of your bicycle fast. How an Industrial Air Compressor Dryer Works This machine will filter out the moisture which keep all those mechanical devices functioning propely.

The second important advantage is utilization and cost-effective dry air-system. Humid air is not good for machines. In fact, more than a third of our homes currently pump out twice as much heat and emit 10 degrees too high, doubling the price they should be on energy bills. Taking advantage of an industrial air compressor dryer increases the system's overall efficiency, which can add up to significant savings on energy costs -- over time. Dry air also helps to maintain the operation of machines and tools as well, ultimately keeping things running smoothly.

Before you learn how it industrial air compression drying works, you need to know that moisture in the form of water vapor is held by the air. When air is compressed in a machine, the pressure inside grows much higher and that really heats things up. When the air cools, water vapor can become liquid in a process known as condensation. This change may bring trouble to the machines and equipment.

An industrial air compressor dryer works through chilling and dehumidifying the squeezed atmosphere. The air being compressed and sent through a filter. It blocks dirt or any solid particles in the air. The air is then introduced to a refrigeration system for treatment after filtration. Also, this phase of cooling is key — because as the air cools down to a point where it forms water droplets (i. e., condensation). Along with a drain valve that removes the liquid water from the dry air. After the moisture has been removed from here, it is ready to be used in machines and tools as dry compressed air.

In using a industrial compressed air dryer we should ensure that the size of the device is suitable for our system, this will help meet reliability standards and prevent damage in case you choose to use an undersized unit. Light of day will peer through if the dryer is undersized and not adequately drying air, so that it may still moist. Alternatively, if the dryer is too large it might end up wasting energy which in turn adds to your costs. We always advise consulting an expert or professional to determine the proper size dryer that will suit your system best.

Thoroughly depending on the industrial air compressor dryer you possess, and general maintenance can also help in keeping your dryers functional. Caring for the Dryer – Cleaning Your Dust Filters and Drain __('in your dryer') Doing these keeps the unit performing at its optimum level. This is also a very critical second to test for leaks in the compressed air system. Sealing any leakages can help in saving the energy and reduce cost to a great extent.

There are several basic factors to consider when you choose an industrial air compressor dryer. So how do you size your air dryer with a compressed air system is what it boils down to. You also must consider the dew point — which is when moisture in your atmosphere will begin to turn into a liquid. However, there are situations where you require a dryer that provides an even lower dew point to dry the air thoroughly.

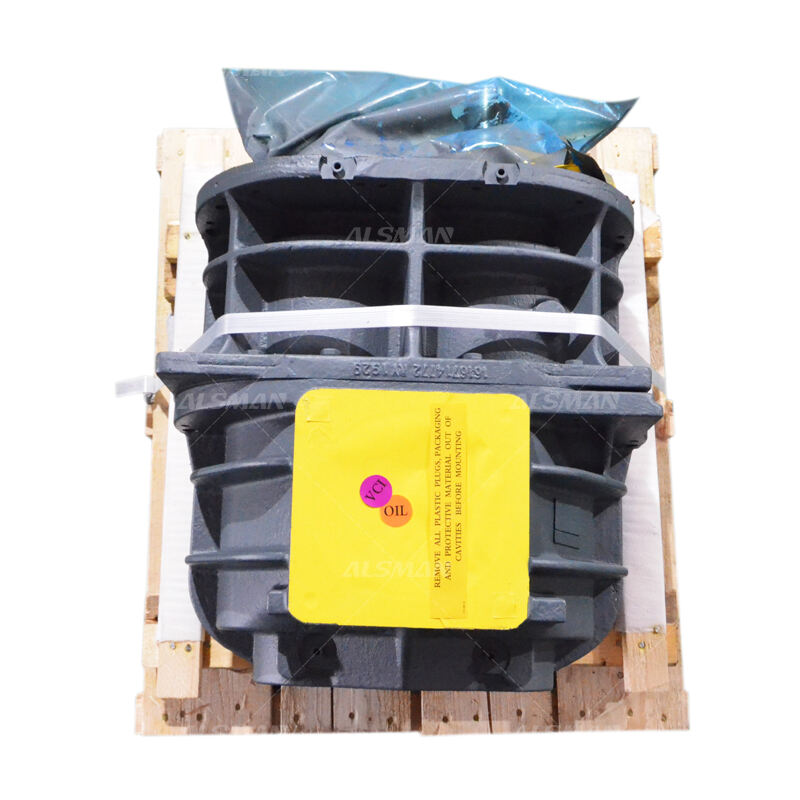

We also provide OEM support for OEM. Our experienced team of technicians and engineers is always challenging the limits of technology to create new solutions that meet the ever-changing needs of our customers. We industrial air compressor dryer for considering Alsman as a trusted partner in compressor excellence.

We can provide everything from custom component design Manufacturing, industrial air compressor dryer, to after-sales service. 24-hour online support is available. At Global Air Compressor Solutions, we know that our customers are the mainstay of our business. We work closely with our clients and understand their specific requirements and issues to offer customized solutions that provide the highest value.

We provide products and solutions for industrial industrial air compressor dryer projects around the world. Include industrial screw air compressors, Air Tanks, Air Pumps Industrial Engineering Machinery Equipments, and other Spare Parts. In addition, We also participates in maintenance projects for motors and also maintains a variety of motors.

Our business mainly offers industrial air compressor dryer, equipments, and accessories for compressors of the world's most renowned brands. We are also engaged in air compression systems as well as vacuum system design consultation Engineering project, repair and maintenance services. We exported to over 60 countries. Products are sold to the United States, Russia, United Arab Emirates, Indonesia, Thailand, Colombia, Saudi Arabia, Mexico, Kazakhstan, South Korea, Morocco, Senegal, Canada, Israel, Bolivia, Peru, Singapore and other countries