Loading ...

Screw type air compressors are specially designed equipment to squeeze the air which makes it stronger and easy way, similar to the Alsmann's product like compressor parts. They are commonly used in many different careers and fields, including constructions or manufacturing sections as well some types automobiles. And it is important to know before installing them that how these machines work and what makes use of them different on other types of air compressors. Which brings us to the correct type of compressors for said knowledge.

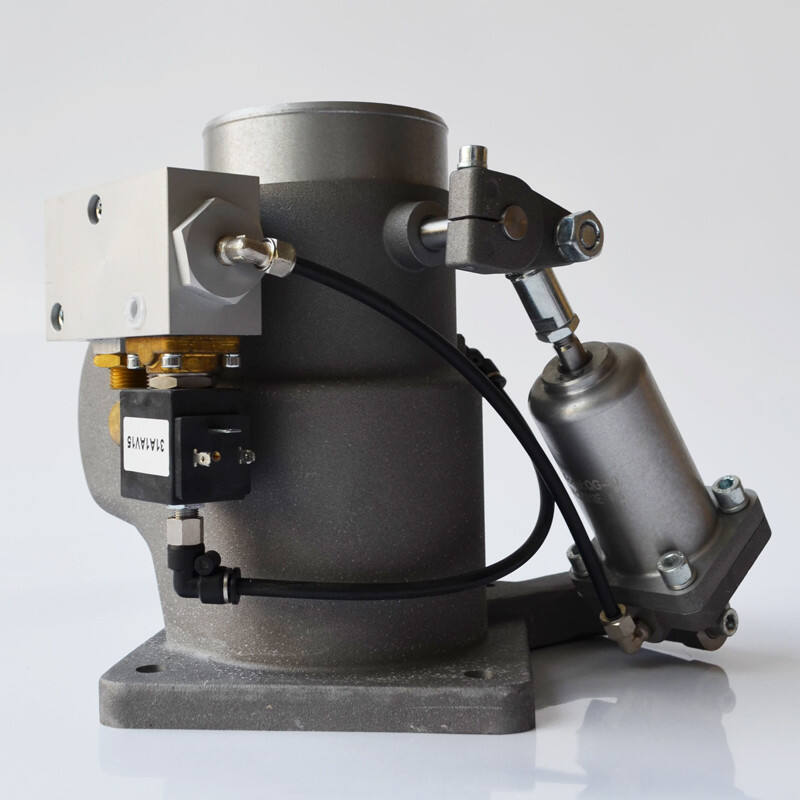

A screw air compressor have two key components by the name of rotors which resides in a casing, identical to air compressor filter and dryer by Alsmann. Special threads on them fit together and create a small pocket of air. The rotors begin to rotate, compressing the air inside that pocket and creating increased pressure in the process. When this air is compressed sufficiently, it flows out through a valve and to wherever the user desires that particular tool or mechanism.

The way screw type air compressors work is one of the things that sets them apart as they offer a steady stream of air with very few starts and stops, the same as Alsmann's air compressor relief valve. That may not always be the case with other kinds of compressors, which are capable for example to provide occasional bursts of air but no in a continuous stream. It spins itself up and stays turning, contributing to a consistent flow of air. This fact renders screw type air compressors especially ideal for applications that require a continuous flow of compressed air (like in factories, where machines are operating at all times).

The amount of air that you will need for your given job is one major consideration when finding the type of screw type air compressor to use, as well as the oil free compressor developed by Alsmann. This will allow you to tell how large and powerful of a compressor that should be used. You will also want to take in mind its decibel rating and other factors of whether you will be using it allot. Different jobs can take different noise levels from a compressor You should also factor in any logistical requirements for your job; are we talking about a compressor fitting into tight spaces or portability?

A screw type air compressor has many benefits, also the Alsmann's product such as air compressor oil filter. They are energy-efficient for one, and so they use less power to do the same job as another machine. A number of units are known for their durability and require little maintenance, so you can depend on them performing when necessary. They also give a stable flow of air, which makes them suitable for tasks that require constant release. Also, they are user friendly and can be remotely controlled which opens up even more possibilities when applying to your tracks. Finally, this type of air compressor can be used in many different areas and industry whether it is for a construction site or manufacturing plant.

Screw type air compressor Supply Solution and products for Industrial Engineering Project in the world. This includes Industrial Screw Air Compressors Air Tanks, Air Pumps, Industrial Engineering Machinery Equipments, as well as other Spare Parts. In addition, We also participates in projects to maintain motors and repairs a range of motors.

We work to create long-lasting relationships by providing exceptional support, service and Screw type air compressor solutions. We also provide support to OEM. Our experienced team of engineers and technicians are constantly pushing the boundaries of technology, creating innovative solutions that meet the ever-changing demands of our clients. Thank you for taking the time to consider Alsman as your trusted partner in compressor top-quality.

We export our products to more than fifty-eight nations. Our goods are well received in the United States, Screw type air compressor, United Arab Emirates (UAE), Indonesia, Thailand Colombia, Saudi Arabia Mexico, Kazakhstan South Korea, Morocco, Senegal Canada, Israel Bolivia, Peru, Singapore and other countries.

We can provide everything from custom component design manufacturing, integration of systems and manufacturing as well as after-sales services. Online service available 24 hours 24 hours a day. Screw type air compressor understands that its customers are at the core of our business. We collaborate closely them to deliver tailored solutions that maximize the value.