Loading ...

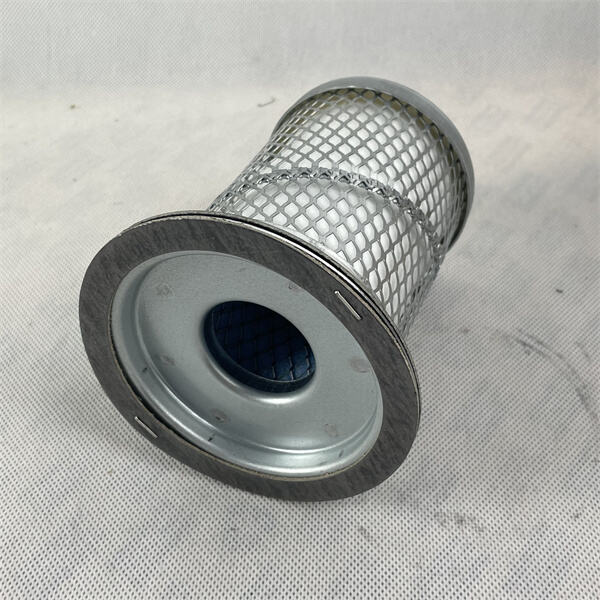

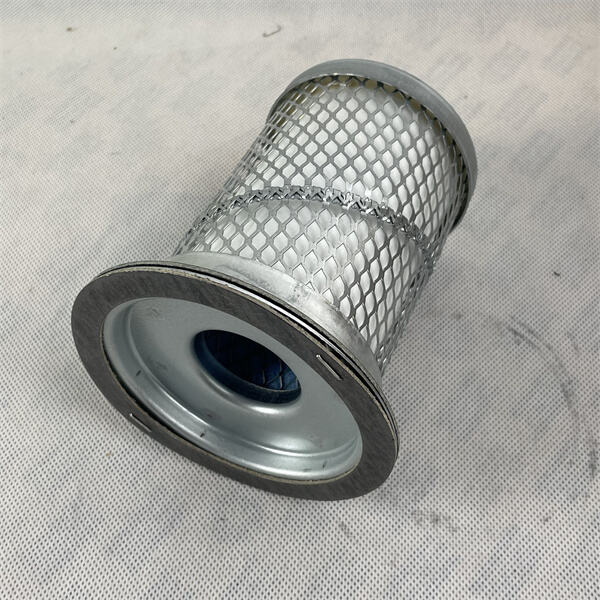

Compressor separators are an essential part of various industries acting as the element in charge for cleaning, or separating the air being utilized by compressor. They remove oil and water from compressed air, therefore eliminating contaminants in the output which not only causes an interruption but also leaves questionable state of cleanliness been uncovered.

Another method to keep compressor separators functioning in the best condition is by cleaning them and monitoring it on a regular basis. Poor maintenance can cause the compressor to malfunction, making it one of the most expensive parts a fridge will ever need. Taking care of the compressor separator will help you save money in time.

There are many things to consider when purchasing a compressor separator, including what the size of your same sized air filter will be like and how much compressed air you'll have produced by your compressors. Moreover, the atmosphere in which your compressor is used will indeed change how well a separator works.

Compressor separator cost savings, oil and water in the compressed air can be removed to reduce maintenance requirements for compressor This will save youthe repair costs and part replacement. A high-quality separator also helps improve the efficiency of pneumatic machines, thus decreasing energy costs.

The performance of your compressor separator all depends on how and where you installed it or the maintenance practices that are associated with proper operation. Regular cleaning, performance check-ups, and adhering to the manufacturer guidelines for maintenance are also required. After performing these steps properly, your compressor separator should function efficiently thus saving money and improving the efficiency of compressors.

To conclude, a compressor separator always plays an important role in protecting compressors from dirty and oily air. Given that all factors indicate the efficiency of these separators, be sure to keep this in mind and it could save you money as well as improve your compressor overall. Proper separator choice, as well regular and thorough maintenance are crucial in avoiding this. A lot of costs and hassles can be avoided in the long run if you know how compressor separators are supposed to work, read up on recommended practices, etc.

We also provide OEM support for OEM. Our experienced team of technicians and engineers is always challenging the limits of technology to create new solutions that meet the ever-changing needs of our customers. We compressor separator for considering Alsman as a trusted partner in compressor excellence.

Our company mainly provides air compressors, equipments, and accessories for compressors made by world-renowned brands. We are also involved in air compression system design and consulting for vacuum systems Engineering project, repair and maintenance services. We exported to over 60 countries. Products are sold to the United States, Russia, compressor separator, Indonesia, Thailand, Colombia, Saudi Arabia, Mexico, Kazakhstan, South Korea, Morocco, Senegal, Canada, Israel, Bolivia, Peru, Singapore and other countries

From custom design of compressor separator and manufacturing, to system integration and after-sales service. 24-hour online support is available. We at Global Air Compressor Solutions, we recognize that our customers are the heart of our business. We are in close contact with our clients, understanding their specific requirements and issues and provide customized solutions that deliver maximum value.

We compressor separator products and solutions for industrial engineering projects around the world. Include industrial screw air compressors, Air Tanks, Air Pumps, Industrial Engineering Machinery Equipments, and other Spare Parts. In addition we participate in projects for motor maintenance and maintains a variety of motors.